Controversy Again: Is Xiaomi's Proud Die Casting Self-Built or Joint Research and Development?

Release time:

2024-05-20

Millet car's big die-casting technology recently caused controversy, millet company spokesman responded that there is a micro-blog deliberately confused the concept of rumors smear. Millet's super large die-casting technology is considered to be the advanced technology of the automotive industry, but the chairman of the second machine tool in Jinan said that the millet stamping line was made by it, raising questions. Xiaomi emphasizes that large die-casting and stamping are different processes and is jointly developed with Haitian.

Millet car's big die-casting technology recently caused controversy, millet company spokesman responded that there is a micro-blog deliberately confused the concept of rumors smear. Millet's super large die-casting technology is considered to be the advanced technology of the automotive industry, but the chairman of the second machine tool in Jinan said that the millet stamping line was made by it, raising questions. Xiaomi emphasizes that large die-casting and stamping are different processes and is jointly developed with Haitian.

On the May Day holiday, the big die-casting technology of millet cars has recently caused a lot of controversy on the Internet.

On May 2, a spokesman for Xiaomi Company's microblog account released a message saying that some microblogs deliberately confused the concept of Xiaomi's super large die casting system and stamping line, spreading rumors and smearing Xiaomi, and there were many acts of spreading rumors and smearing. Comprehensive evidence has been obtained to safeguard their legitimate rights and interests.

In fact, the controversy about Xiaomi's super-large die-casting technology is not only in recent days. But at the end of last year after the millet car technology conference so far, the controversy has been constant.

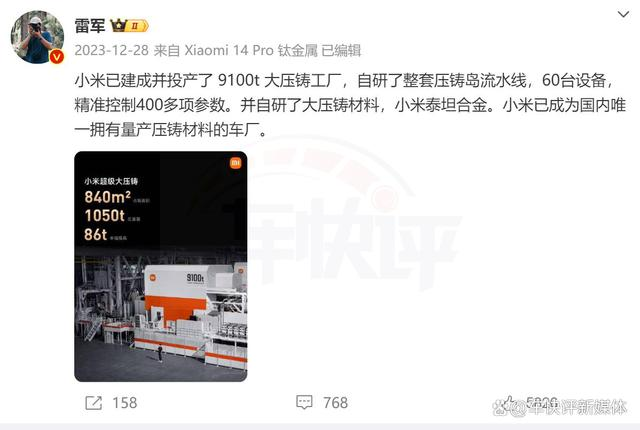

Millet car technology conference, millet chairman Lei Jun for the first time announced the millet super big die casting technology. It is understood that the core of Xiaomi's super die-casting technology is a large die-casting machine with a clamping force of 9100 tons and a weight of 718 tons. Xiaomi official said that compared with the traditional process, Xiaomi's die-casting machine has high production efficiency and solid and reliable parts. It is the pearl of the current application of new technologies in the automotive industry. At the same time, Xiaomi officials also said that Xiaomi is also the only automobile manufacturer in China that has both self-developed die-casting alloy materials and self-developed large die-casting equipment cluster systems.

In addition, Xiaomi also emphasized that it has built a large die-casting factory and completed the full stack self-research of almost all links in the large die-casting industry chain.

According to the official information released by Xiaomi, Xiaomi Super Die Casting has obtained the dual professional certification issued by the China Automotive Engineering Society and the National New Energy Vehicle Technology Innovation Center, which is at the international advanced level. Lei Jun even calls it an "industrial behemoth". From the above, we can see that Xiaomi's big die casting technology is really good. At the very least, in the eyes of Xiaomi and Lei Jun, the big die-casting technology should be the best proof that Xiaomi cars have core technology. Mention one-piece die-casting technology, in the traditional fuel car era rarely heard. Until the emergence of new energy vehicles, the word "big die casting" was known to us. To put it simply, the large die-casting technology uses an ultra-high pressure die-casting machine to form a plurality of automobile aluminum alloy parts at one time, which can reduce the parts and welding processes required by the automobile. It can not only greatly reduce the weight of the car body, improve the utilization rate of the interior space and increase the torsional rigidity of the car body, but more importantly, it can effectively reduce the cost of making the car.

Among new energy car companies, Tesla should be the first car company to widely use large die-casting technology. Today, in addition to Tesla and Xiaomi, large die casting technology has been applied to car companies including Wei Xiaoli, Wenjie and Krypton. Among them, Xiaomi is the only car company that has already used large die-casting technology on its first model.

The reason why the dispute about Xiaomi's big die-casting technology has reopened recently is that Zhang Shishun, chairman of Jinan No. 2 Machine Tool Group Co., Ltd., made it clear in an interview with the media that Xiaomi's stamping line was made by Jinan No. 2 Machine Tool. As soon as this statement came out, many people questioned millet's big die casting technology.

Therefore, a spokesperson for Xiaomi also made it clear that large die-casting and stamping are two completely different processes. In the millet car factory, the two also belong to different workshops. Millet super big die-casting, is millet and Haitian joint research and development.

According to the social platform car review, chairman lei jun made it clear at the end of last year that Xiaomi had built and put into production a 9100t die casting factory. now a spokesman for Xiaomi company said that Xiaomi die casting was jointly developed with Haitian. which statement is more credible?

Related News